Hot Melt Adhesives are Essential in Filter Production

Hot melt adhesives play a pivotal role in the manufacturing and assembly of various types of filters, from air and water filtration systems to industrial-grade filters used in automotive and HVAC applications. Their unique properties—such as quick setting times, strong bonding capabilities, and adaptability to diverse materials—make them indispensable for filter production.

This article delves into how hot melt adhesive companies contribute to the development of advanced filter solutions, the benefits of their use, and the industries that rely on them.

Hot melt adhesives have revolutionized the filter production industry by offering fast, reliable, and versatile bonding solutions. From air and water filtration to automotive and medical applications, these adhesives ensure the durability and efficiency of modern filters.

As adhesive companies continue to innovate, the future of filter production will see even greater advancements in performance, sustainability, and design possibilities. For manufacturers seeking high-quality and efficient filter solutions, hot melt adhesives remain the ideal choice.

Key Characteristics of Hot Melt Adhesives in Filters

- Strong Bonding Strength: Provides durable adhesion for filter components like media, frames, and housings.

- Flexibility: Maintains structural integrity under pressure and vibration.

- Temperature Resistance: Withstands extreme hot and cold conditions during operation.

- Chemical Compatibility: Resists degradation from exposure to water, oils, and other chemicals.

- Quick Setting: Speeds up production processes, especially in automated assembly lines.

Advantages Over Mechanical Fasteners and Traditional Adhesives

- Eliminates the need for screws, rivets, or clips, reducing weight and improving filter design.

- Seamlessly bonds irregular shapes and non-uniform surfaces.

- Ensures a clean, leak-proof seal without gaps.

Applications of Hot Melt Adhesives in Filter Production

- Air Filters

Air filters, used in HVAC systems, vehicles, and industrial equipment, require precision and durability in their construction.

- Common Components Bonded:

- Filter media to the frame or housing.

- Pleated media stabilization.

- Key Benefits:

- Creates an airtight seal to prevent unfiltered air from bypassing.

- Resists environmental factors like moisture and temperature changes.

- Water Filters

Water filtration systems depend on robust adhesives to maintain leak-proof seals and durable construction.

- Applications:

- Securing filter cartridges in their housing.

- Bonding pleated or layered filter media.

- Benefits:

- Resists water pressure and chemical exposure.

- Ensures long-lasting performance without compromising filtration efficiency.

- Automotive Filters

Automotive filters, such as oil, fuel, and cabin air filters, operate under extreme conditions and require adhesives with high performance.

- Uses in Automotive Filters:

- Bonding filter media to caps or end plates.

- Sealing edges to prevent leaks.

- Advantages:

- Withstands high temperatures and exposure to oils and fuels.

- Maintains adhesion despite vibration and mechanical stress.

- Industrial Filters

Filters used in heavy machinery, manufacturing plants, and power plants demand durable and precise bonding.

- Applications:

- Bonding large filter elements for dust collection.

- Securing HEPA filters in cleanrooms.

- Key Benefits:

- Handles high pressure and large-scale filtration needs.

- Provides reliable performance in harsh environments.

- Medical Filters

Medical-grade filters, such as those used in respiratory equipment and sterilization systems, require non-toxic and reliable adhesives.

- Applications:

- Securing membranes and media in filter cartridges.

- Creating leak-proof seals for sterile environments.

- Benefits:

- Complies with strict medical and safety standards.

- Provides precision bonding for small, delicate components.

Custom Adhesive Formulations

Hot melt adhesive manufacturers develop specialized formulations tailored to specific filter applications, addressing unique challenges like temperature resistance, chemical exposure, and mechanical stress.

- Eco-Friendly Solutions

Many companies are prioritizing sustainable adhesive options that reduce environmental impact while maintaining high performance.

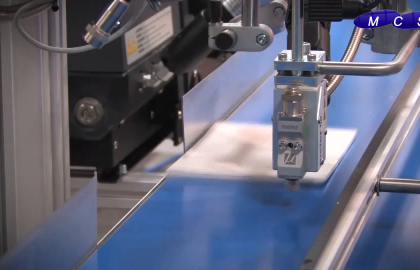

- Advanced Application Techniques

Hot melt adhesives are applied using precision equipment, such as bead, swirl, or spray nozzles, to ensure even coverage and optimal bonding.

- Collaboration with Filter Manufacturers

Adhesive production companies work closely with filter manufacturers to test and optimize adhesives for their specific products, improving efficiency and performance.

Benefits of Hot Melt Adhesives in Filter Production

- Enhanced Durability: Ensures filters remain intact and functional under demanding conditions.

- Design Freedom: Supports complex designs, such as pleated or layered filters.

- Reduced Waste: Precise application minimizes adhesive usage.

- Increased Production Efficiency: Fast-setting adhesives speed up manufacturing.

- Improved Aesthetics: Seamless bonds create a clean, professional finish.

Challenges and Solutions in Filter Production with Hot Melt Adhesives

- Material Compatibility:

- Challenge: Different filter materials may require unique adhesive properties.

- Solution: Adhesive companies provide tailored formulations for various substrates.

- Temperature Sensitivity:

- Challenge: Filters used in extreme environments may experience adhesive failure.

- Solution: Use adhesives engineered for high-temperature or cold-resistant applications.

- Regulatory Compliance:

- Challenge: Medical and food-grade filters must meet strict safety standards.

- Solution: Non-toxic, FDA-approved adhesive options are available.

- Sustainability: Increased focus on biodegradable adhesives and eco-friendly production methods.

- Smart Filters: Adhesives integrated with sensors for real-time monitoring and performance tracking.

- Advanced Formulations: Improved resistance to chemicals, temperature extremes, and wear for next-generation filters.