Rubber-Type Mattress Foam Adhesive (Latex + Sponge)

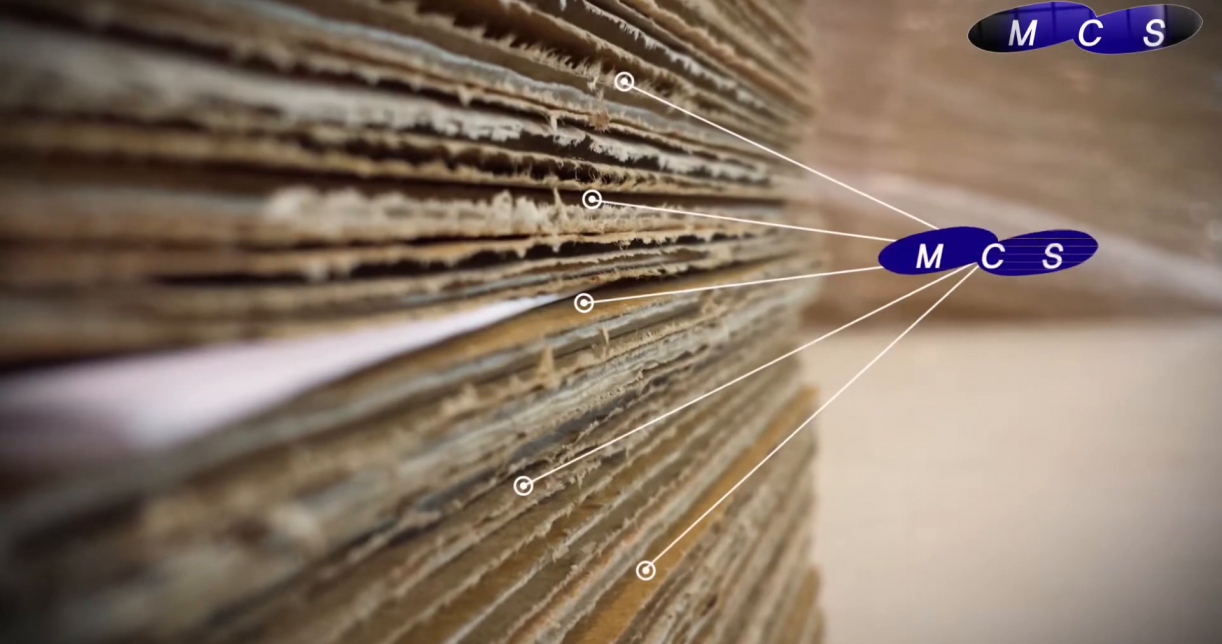

Hot melt adhesives are crucial in the mattress manufacturing industry, ensuring that various components like latex, sponge, and pocket springs are securely bonded for long-lasting comfort and durability. Rubber-type and olefin-type adhesives are two key formulations widely used in this industry. Both types are tailored to meet the unique demands of mattress assembly, including flexibility, strength, and compatibility with diverse materials.

This article explores the use of these adhesives in mattress production, focusing on latex and sponge foam bonding, pocket spring assembly, and the benefits they bring to the manufacturing process.

Rubber-type and olefin-type hot melt adhesives are revolutionizing the mattress industry, enabling manufacturers to create durable, comfortable, and high-quality products. From latex and sponge bonding to pocket spring assembly, these adhesives ensure precision and reliability at every step of the process.

As technology advances, hot melt adhesive production companies will continue to innovate, delivering solutions that meet the evolving demands of mattress manufacturers and consumers worldwide.

Rubber-type adhesives are formulated with synthetic or natural rubber as the primary base. These adhesives offer high elasticity and strong bonding, making them ideal for applications that require flexibility and durability.

Applications in Mattress Manufacturing

- Latex Foam Bonding:

- Provides a strong and elastic bond for natural and synthetic latex foams.

- Ensures durability while maintaining the foam’s natural flexibility.

- Sponge Foam Adhesion:

- Secures sponge layers with precision and prevents delamination.

- Ideal for multilayer mattress constructions that require soft but sturdy connections.

- General Layer Bonding:

- Bonds foam to fabric, ensuring a smooth and durable finish.

Key Features and Benefits

- High Elasticity: Maintains integrity under repeated compression.

- Strong Adhesion: Ensures a long-lasting bond, even under heavy use.

- Temperature Resistance: Performs well in various climates, ensuring mattress durability in global markets.

- Non-Toxic Formulation: Safe for use in household products, adhering to industry health and safety standards.

Olefin-Type Mattress Foam Adhesive (Latex + Sponge)

What is an Olefin-Type Adhesive?

Olefin-type adhesives are made using polyolefin polymers, which provide strong adhesion while being lightweight and environmentally friendly. These adhesives are increasingly popular in the mattress industry for their sustainability and high-performance characteristics.

Applications in Mattress Manufacturing

- Latex and Sponge Bonding:

- Provides a seamless bond between latex and sponge layers without compromising breathability.

- Ensures stability and strength for foam constructions.

- Pocket Spring Encapsulation:

- Bonds pocket springs to foam or fabric layers in hybrid mattress designs.

- Creates a secure and uniform structure for optimal performance.

- Edge Support Systems:

- Secures foam rails and edge reinforcements, preventing deformation over time.

Key Features and Benefits

- Eco-Friendly: Low VOC emissions and recyclable formulations.

- Lightweight Performance: Enhances mattress portability without compromising strength.

- Heat Resistance: Maintains adhesion integrity in temperature-sensitive applications.

- Fast Setting: Ideal for high-speed production lines, improving manufacturing efficiency.

Pocket spring mattresses require precise bonding to secure individual springs within fabric casings, ensuring optimal support and motion isolation. Both rubber-type and olefin-type adhesives are commonly used for this purpose.

Applications

- Spring-to-Fabric Bonding: Adhesives ensure the springs remain securely encased within the fabric pockets.

- Row Connection: Bonds multiple rows of pocket springs together for a cohesive and durable mattress core.

- Hybrid Designs: Facilitates the integration of pocket springs with latex, sponge, or other foam layers.

Benefits of Hot Melt Adhesives in Pocket Springs

- Flexibility: Allows springs to move independently for better contouring.

- Strength: Prevents displacement or detachment during mattress use.

- Durability: Ensures long-lasting performance even under continuous compression and movement.

Comparison of Rubber-Type and Olefin-Type Adhesives for Mattresses

| Feature | Rubber-Type Adhesives | Olefin-Type Adhesives |

| Elasticity | High elasticity, suitable for soft foams | Moderate elasticity with high strength |

| Environmental Impact | Generally higher VOC emissions | Low VOC emissions, eco-friendly |

| Temperature Resistance | Excellent in varying climates | Superior in high-temperature applications |

| Setting Time | Moderate | Fast, ideal for high-speed production |

| Durability | Highly durable under compression | Long-lasting and lightweight |

- Enhanced Efficiency: Quick setting times improve production speed.

- Versatility: Suitable for various mattress materials and designs.

- Durability: Provides long-lasting performance, even under heavy use.

- Eco-Friendliness: Olefin adhesives offer sustainable solutions for environmentally conscious manufacturers.

- Safety: Non-toxic formulations ensure safe handling and consumer use.

Future Trends in Mattress Adhesives

- Sustainability: Increasing demand for biodegradable and recyclable adhesives.

- Smart Adhesives: Integration with sensors for advanced mattress functionality.

- High-Speed Formulations: Faster setting adhesives to meet growing production demands.

- Enhanced Breathability: Adhesives designed to maintain airflow in foam layers for cooler sleep experiences.